How do I get rid of a block contamination error on my Agilent AriaMX?

The recommendation is to clean the wells, the heat block and surrounding areas, and the filter cartridges.

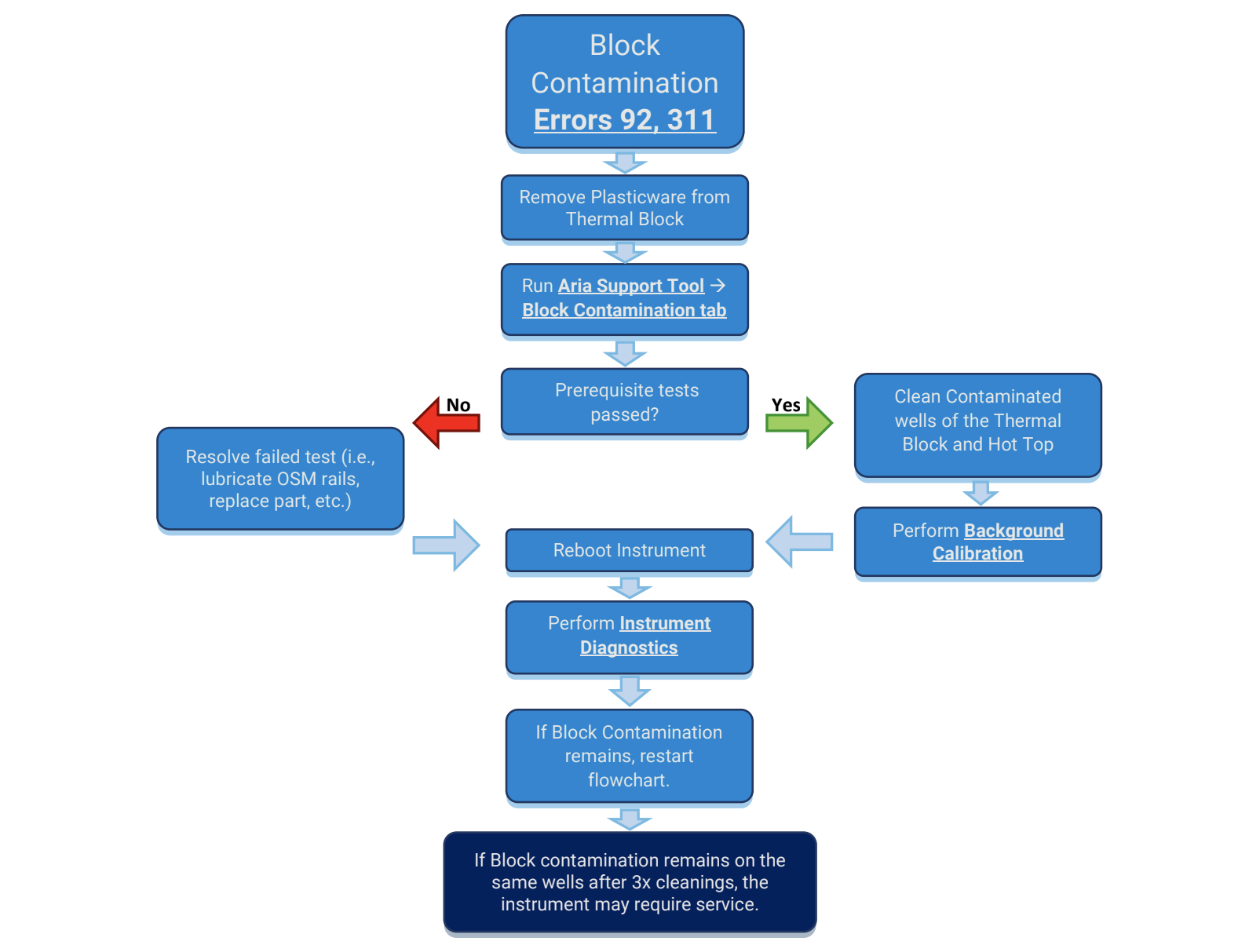

A Block Contamination error is commonly caused by dirt/debris or scratches in or around the heat block area of the instrument which affects surface reflection characteristics used for background signal level calculations. In some cases, the block contamination test may fail due to a failure in a prerequisite diagnostic test. These prerequisite diagnostic tests are performed in conjunction with the block contamination test, and they test various aspects of instrument function that could impact the fluorescence readings measured during diagnostics. The flowchart below illustrates how to address a Block Contamination Error.

Download the Aria Support Tool.

Performing a Background Calibration.

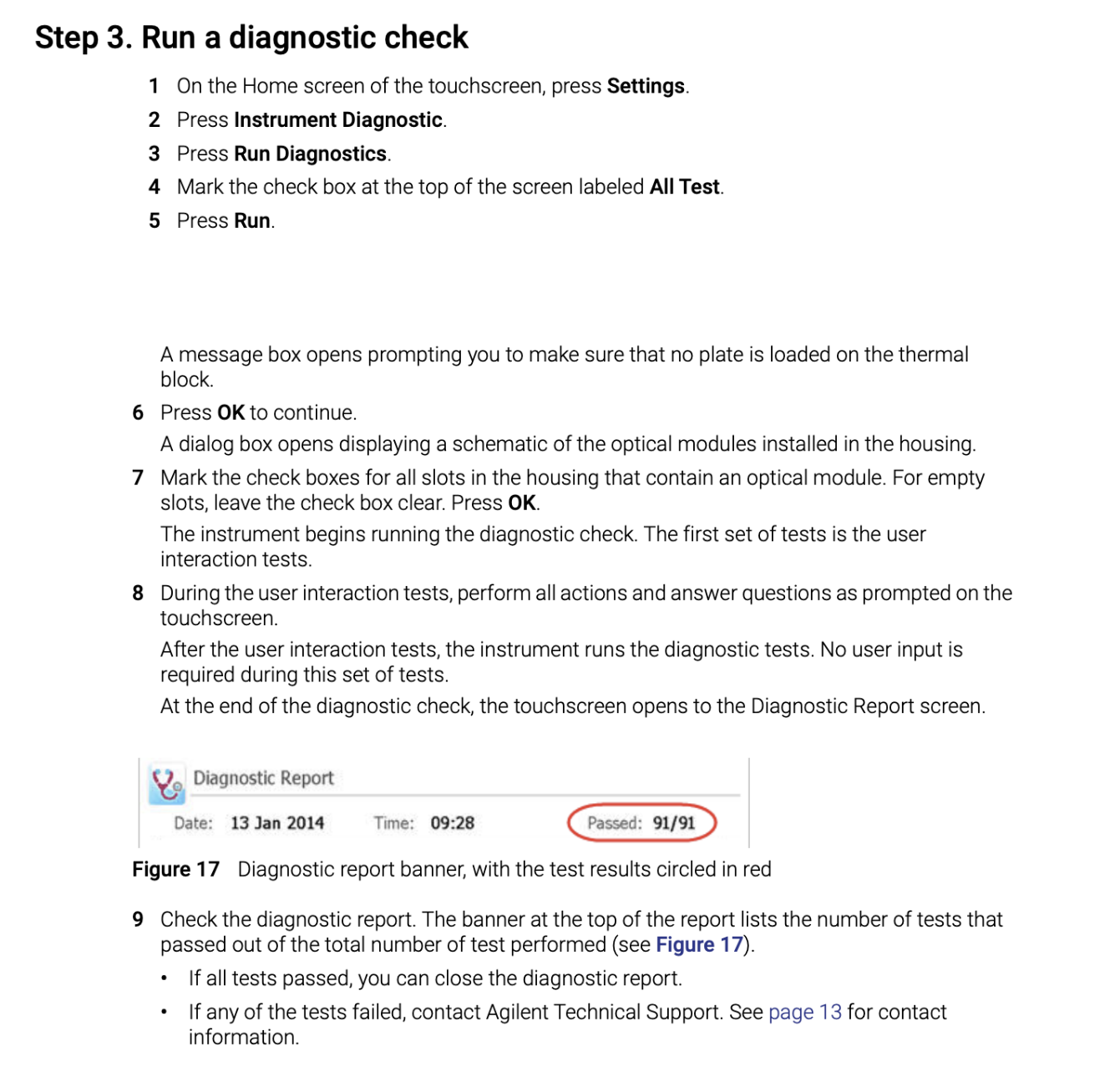

Performing a Diagnostic Check:

The recommendation is to clean the wells, the heat block and surrounding areas, and the filter cartridges.

Please see below the protocol for cleaning.

- Turn off Instrument.

- Remove the power cable from the rear of the instrument.

- With the power off, carefully move the Optical Module Housing to the far left side of the Instrument.

- Open the instrument Hot Top Lid.

- Remove any existing plasticware from the instrument.

- Use compressed air to remove dust from the Hot Top lid, Thermal block wells, and surrounding area.

- Wipe down the Hot Top lid, Thermal Block, and surrounding area with a lint-free cloth.

- Visually inspect wells with 2-3x magnifier light for remaining debris.

- Re-perform the full suite of Instrument Diagnostic tests to confirm contamination has been cleared and error has been resolved.

- Clean wells with 70% isopropyl using a V-shaped cotton swab (Agilent PN 9300-2574) or similar.

- Allow wells to dry completely.

- Perform Background Calibration.

- Re-boot Aria Instrument.

- Re-perform the full suite of Instrument Diagnostic tests to confirm contamination has been cleared and error has been resolved.

- Wipe down the hot top lid and block with a moistened lint-free cloth or Kim Wipe.

- Check that protective strips removed from bottom of all optical cartridges. Wipe the bottom of each cartridge with a clean, lint free cloth or lens paper.

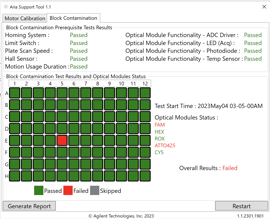

- Import diagnostic report file (.res) into the Aria Support Tool and address failing wells with further cleaning. The entire diagnostic procedure must completed so that the Aria Support Tool may read the .res file.

- If the error persists, fill all wells with 120 ul deionized H2O with multichannel pipettor and clean each using a q-tip. Afterwards, carefully remove all the water, then add 120 ul 70% ethanol or isopropanol to each well, then remove it. Heat the block to 95˚C for 2 min to allow it to completely dry.

- If Block Contamination error persists after three repeated cleanings, please reach out to your Medicinal Genomics Account Manager in the United States and Agilent Technical Support center for other locations*.

*To contact the local Agilent Technical Support center, use the following link:

Select the appropriate country from the drop-down menu and locate the phone number and email address from the Genomics section.

T: +1 800 227 9770 , Option 3-4